TENARIS Steel Sucker Rod

Fully integrated

manufacturing

Process

Technologies for the most challenging wells and environments

Penta uses real-world data to determine the best steel rod for your wells

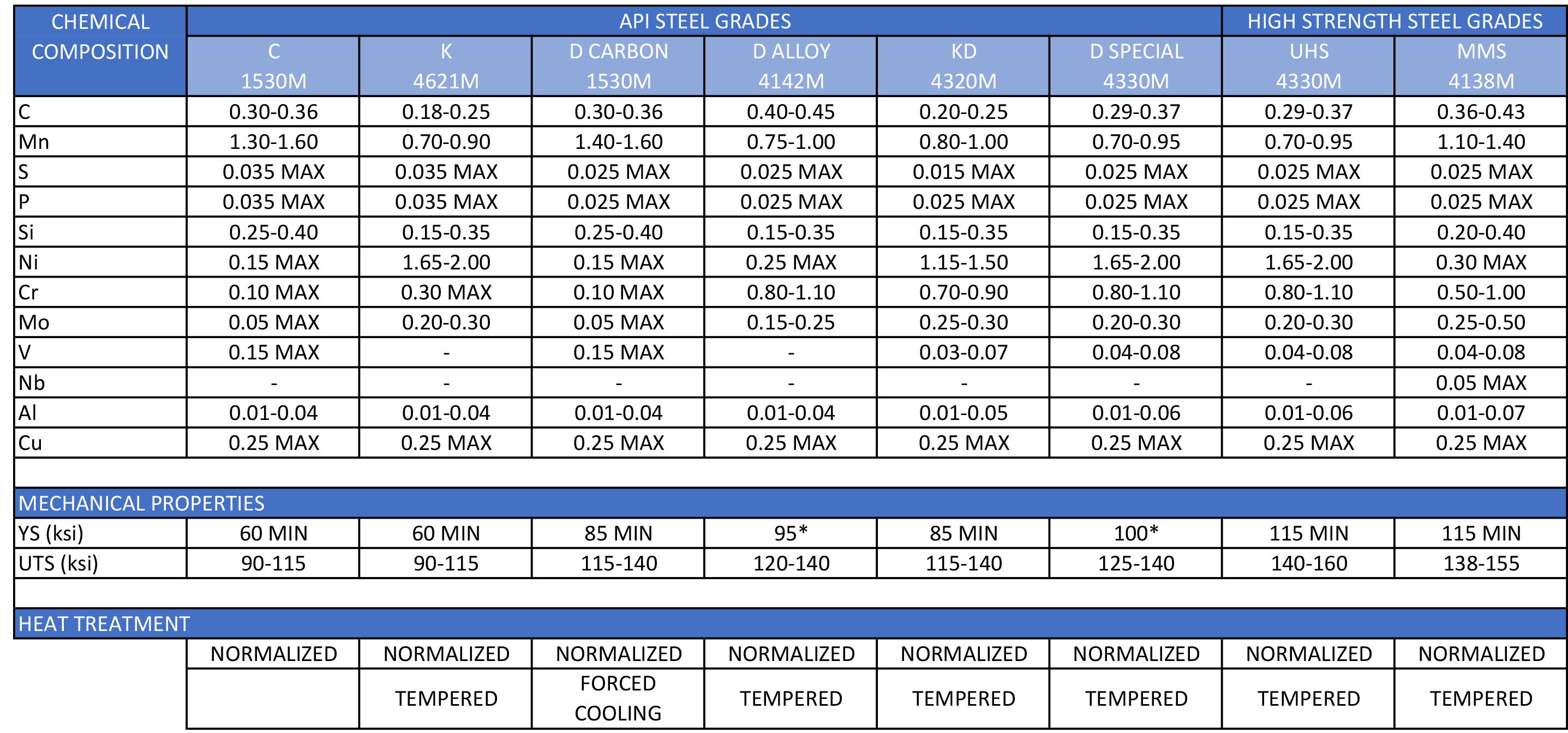

Tenaris’s sucker rods and accessories are designed to efficiently respond to challenging operating conditions,

including high loads, corrosive environments and applications where control of tubing/rod friction is required.

Manufactured to the most stringent quality standards, all product lines comply with ISO 9001 and API Q1

specifications. A single quality policy and the enforcement of a rigorous quality management system ensure

homogeneous quality across all facilities. Quality control procedures include statistical process controls, daily

process/product audits and sucker rods traceability systems. Each individual rod is straightened, while its

entire surface is inspected by Non Destructive Testing (NDT) equipment that can detect any potential

transversal or longitudinal defects in accordance with API criteria. Internal ultrasonic tests are also performed.

Additionally, all Tenaris sucker rods undergo a shot peening process that compresses their external surface to

improve fatigue resistance.

With almost 4 decades of experience in rod pump optimization, including early adoption of remote monitoring

technologies along with full dynamomometer & fluid level services, Penta Completions has the ability to identify

potential rod problems before the well is equipped. Tenaris’ Steel Sucker Rods provide the quality needed to

ensure that the product is up to the task.

Successfully pumping modern wellbores does require more then just a high quality sucker rod so Penta will

also aid in selecting the correct SPM Oil & Gas guiding configurations for your horizontal and directional wells.

With a full range of molded rod guides for both paraffin and deviation control stocked at all of our field locations,

Penta will work to ensure that your wells are given the best chance to achieve run lives that enhance the

profitability of your operations.